Services

Swedabo offers brand new or second-hand woodworking equipment and machinery parts for sale. We can also adjust woodworking equipment to your production facilities, and fill all of your specific needs with the help of our technical designers. If you are looking for used or new woodworking equipment, spare parts or want to repair it, then this is the right place to start!

We, as specialists and enthusiasts of industrial woodworking equipment, are here to help you and your company achieve maximum efficiency at every stage of production and working hours!

We can and will help you with the following:

- Find used or new industrial machinery;

- Sell your old equipment;

- Order individually made woodworking machines;

- Help with equipment dismantling;

- Check what's wrong with your equipment;

- Help with installation and maintenance.

Punctuality, high quality, in-depth communication and professional approach are our core values in mutual cooperation from both sides. We go into every situation and recommend the best solution for it. And we know – time and costs are very important to the enterpreneur today. Our goal is to reduce overall costs by reducing the involvement of human resources and equip the entrepreneur to produce more in the shortest possible time.

Swedabo Services

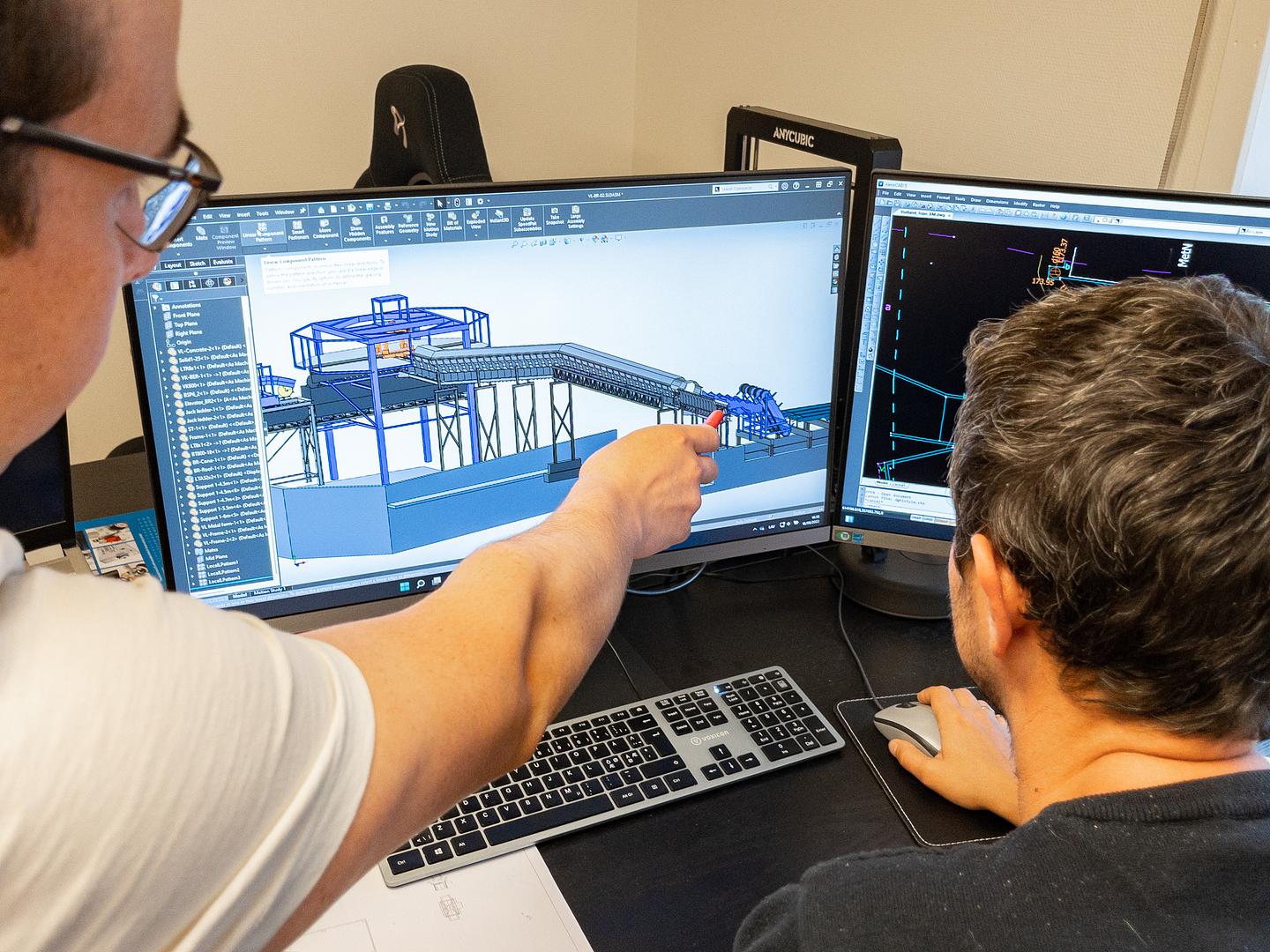

Design and customization

New world requires enterprises to be flexible in each project they work on. To keep up with the times Swedabo has also developed a professional engineering team that specializes in design engineering and provides a full suite of CAD drawing and engineering services. Our engineers are experienced and capable of taking on any project. We design parts, machines and production plants to improve production efficiency.

We can provide:

- Equipment design;

- Development of production flowsheets;

- Engineering calculations and simulations;

- Preparation of technical drawings and documentation;

- Equipment manufacturing consultations.

This method is fast, simple and accurate at the same time, providing volume and component measurements of various production equipment using 3D scanning.

The scanning is carried out using specialised equipment which produces a 3D point cloud model of the object. This point cloud can be developed as a 3D model to be used as a physical object in computer simulations, design, manufacturing and planning. A model of a machinery can also be created using a 3D printing machine.

Benefits of 3D scanning:

- Technical solutions for equipment;

- Cuts and assemblies;

- Modelling of situations;

- Implementation of various monitoring;

- Analysis of objects and visualisation of design solutions;

- Scaned data can be combined with aerial photography, which also allows individual elements to be added for modelling and processing;

- In a short time, the 3D scanner allows to obtain high-precision (up to 0.1mm) data on object dimensions, surfaces, displacements, reflected by real object colours, in a 3D point cloud (colour, black or white), in different formats.

Manufacture

It is often difficult to find equipment suitable for your sawmill which meets the parameters of the room and space from the equipment offered on the market, therefore all you have to do is order an individually designed woodworking equipment. The good news for you, Swedabo can help you with the individual equipment creation process from A to Z. Our skilled professionals are educated and have many years of experience in woodworking machinery production from feeding tables for saws to board sorting equipment and etc. Years of practicing have made us experts in this area. The Swedabo team manufactures equipment that is binding to the main equipment, such as step feeders for sawmills, board packing lines, board sorting, log sorting, board tables, chain conveyors for logs, belt conveyors, roller conveyors and other metal processing works. Contact our team for more information about the manufacturing process and our other services you are interested in.

Maintenance

Equipment for the woodworking industry is manufactured to be as durable as possible in order to extend its service life. However, it is also important to keep the equipment in good working order and, in case of damage, repair the necessary parts. We would gladly use our great experience in woodworking equipment repair and maintenance to help you with fixing any kind of technical problems with machinery. Contact us if you need any help: assess the situation and find the cause of the damage or repair and replace equipment, in case of major damage.

Interested in equipment restoration? At the moment we are very well specialized in peelers. We can repair the equipment according to the customer's wishes. Assembly - restoration works - peelers, saws, splitters, packers, conveyors, log tables, and whole working lines. You can restore everything you need, bearings, running gear, gears, cylinders, electronics.

Consultation

Aside from production, sale, repair, and transportation of woodworking equipment, we provide consulting services and assistance in finding the best woodworking equipment solutions that meet your or your company's needs. We will be happy to help you find answers to specific questions about equipment, production lines, equipment maintenance and repair, spare parts, and other related questions in this industry.

Installation

Need help installing your woodworking machine?

Swedabo offers to build and install, as well as install already purchased equipment. Our team will be able to install both complex metal frames and the entire control system, electronics, etc. so that you can operate the equipment immediately. We assemble all types of sawing equipment and sawmills, lines, conveyors, peelers, planers moulders, etc.

Find out more about Swedabo!